June 22, 2010

Cyclones have been used to separate solids from gas streams since the middle of the nineteenth century. These devices are used in a variety of industry applications and cover a wide range of operating parameters. Early researchers conducted experiments to understand the operation of cyclones and to develop design correlations. Zenz (1975) developed an empirical procedure which has become a common basis for most cyclone applications. Others including Muschelknautz (1970) have developed theoretical models to describe and predict cyclone operation. Cyclone manufacturers have used the results from this early research along with field experience, inspection history, and troubleshooting to develop their own design guidelines in order to improve performance and equipment reliability. However, industry continues to demand improved cyclone performance and longer equipment life based upon process improvement, government regulations, environmental emissions, and overall profitability. The PSRI Cyclone Program attempts to meet this need by conducting fundamental research and testing in the following areas:

-

•Dipleg Termination,

-

•Modeling & Design, and

-

•Erosion.

Historically, cyclones were tested in a batch configuration with an ideal inlet and at relatively low solids loadings (< 0.1 lb/ft3) for the following reasons:

-

•They were harder to set up and run continuous circulating systems,

-

•Higher solids loadings were harder to achieve in a batch mode, and

-

•Test materials of typically (< 20 microns) were used.

Years of experience running circulating fluidized beds and high velocity fluidized beds at PSRI leads us to believe that cyclones have to be tested in a continuous circulating mode after the solids reach an equilibrium size distribution in that particular circulating system. Cyclones are part of a system (fluid bed, riser, conveying line, etc.) and as such need to be tested as part of a given system. De-coupling cyclones from the system leads to erroneous cyclone designs and conclusions. Cyclones should be tested as part of a system similar to installations in commercial units.

The objectives of the Modeling & Design Cyclone Program are to:

-

•Develop a predictive tool for conventional cyclones to estimate overall pressure drop, collection efficiency, and fractional efficiencies for both tangential and volute type cyclones. They need to include the impact of gas viscosity & density, cyclone geometry, solids loading, and particle properties,

-

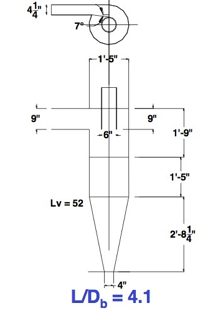

•Determine the effect of advanced high aspect ratio cyclone types and parameters to identify the next generation cyclone design for high solids loading applications, and to develop a predictive tool to estimate overall pressure drop, collection efficiency, and fractional efficiencies,

-

•Determine the major variables and mechanisms affecting cyclone erosion in low solids loaded systems,

-

•Determine the effect of vortex stabilizers and/or dust hoppers on erosion,

-

•Determine the effects on cyclone operation utilizing different cyclone exit configurations, aeration and valve designs, and

-

•Develop a model for streaming flow in diplegs. (Done except for delivery of spreadsheet tool).